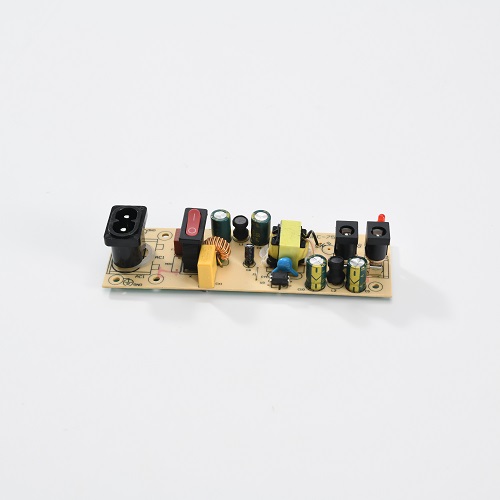

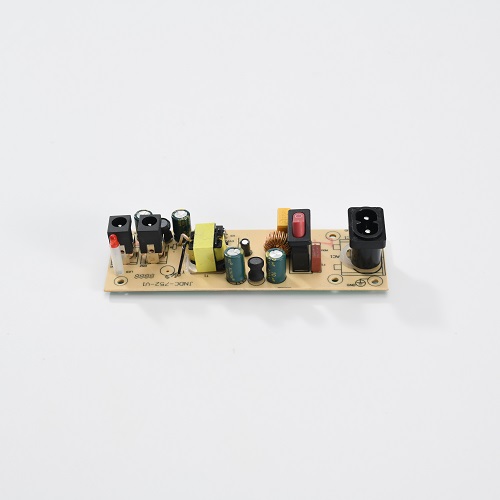

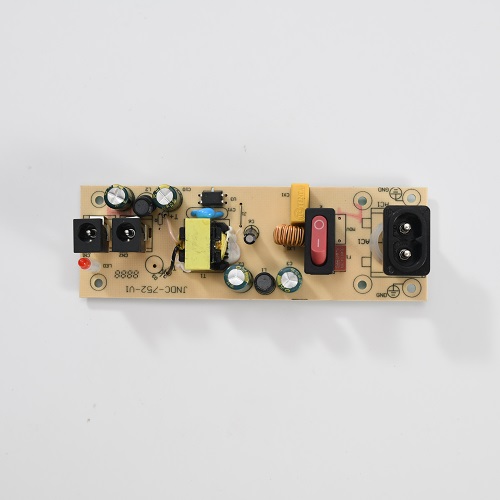

AC~DC Power Board is an electronic device used to convert alternating current (AC) to direct current (DC). It is a power conversion device, usually used to provide stable DC power for various electronic devices. In this process, AC~DC Power Board converts the input AC voltage (such as 110V or 220V in the home power socket) into the required DC voltage (such as 5V, 12V, 24V, etc.) to meet the working requirements of electronic products.

This device is widely used in many fields such as consumer electronics, industrial equipment, power adapters, LED lighting, power tools, communication equipment, etc. It plays a vital role in power electronics technology, especially in devices that require stable DC power, and is one of the core components for achieving power conversion.

Uses:

Home appliances: Many modern home appliances such as televisions, refrigerators, audio equipment, etc. need to convert the AC power in the home into DC power suitable for the internal circuit. AC~DC Power Board can provide stable DC power for these devices.

Computers and peripherals: Personal computers, servers, monitors, printers and other devices usually require efficient and stable DC power supply. AC-DC Power Board is responsible for converting the AC power in the power socket into the DC voltage required by the adapter device.

Communication equipment: Including wireless communication base stations, routers, switches, etc., these devices need to convert AC power into low-voltage DC power to ensure the efficient operation of the system.

Industrial equipment: Industrial automation control systems, instrumentation, LED lighting equipment and other fields also require AC-DC power boards for power conversion.

Battery charger: In power tools, electric vehicles, portable devices and other fields, AC-DC Power Board is used as the core part of the battery charger, which charges by converting AC power into DC power.

In addition to these common uses, AC-DC Power Board can also be used in some special fields, such as medical equipment, power monitoring instruments, vending machines, etc., all of which require stable and reliable power supply.

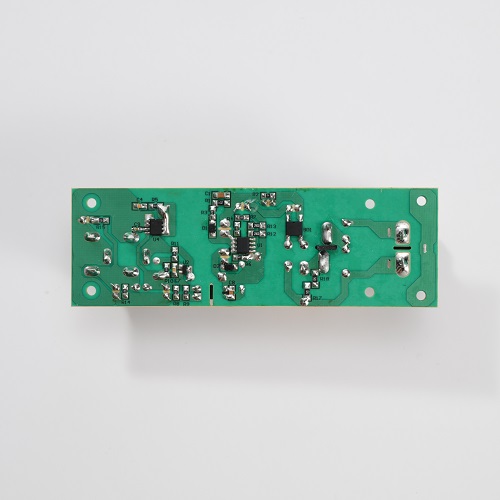

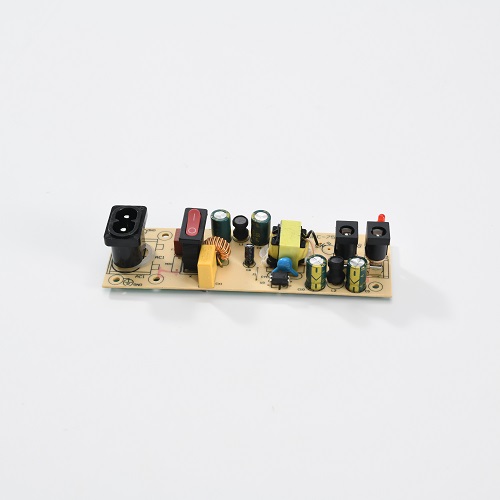

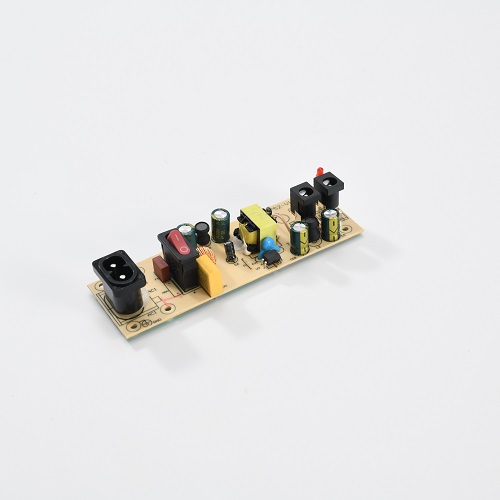

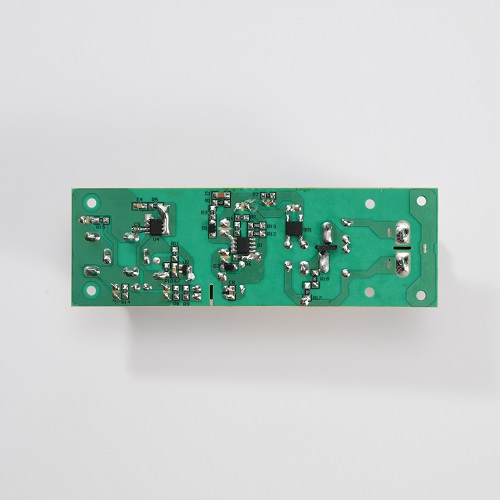

Material:

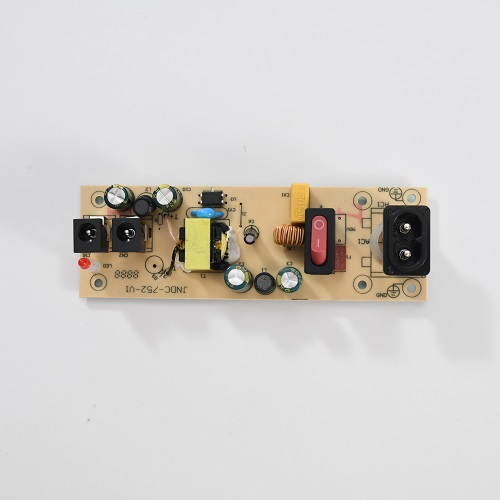

PCB (Printed Circuit Board): The core component of AC-DC Power Board is usually a printed circuit board (PCB). A variety of electronic components are arranged on the PCB, such as capacitors, resistors, diodes, rectifier bridges, etc. The PCB material is usually FR4 (glass fiber substrate) or aluminum substrate. FR4 material has good heat resistance and mechanical strength, and is suitable for general electronic devices. Aluminum substrate has better heat dissipation performance and is suitable for high-power AC-DC conversion applications.

Metal components: High-quality metal materials (such as aluminum, copper, iron alloy, etc.) are often used on components such as rectifier bridges, filter capacitors, and voltage regulator chips to ensure the conductivity and heat dissipation of the circuit. Especially in high-power devices, the thermal conductivity of metal components is crucial.

Plastic shell: The shell of the power board is generally made of flame-retardant plastic or ABS plastic. These materials can not only effectively protect the circuit board and prevent damage to the power board from the external environment, but also play a role in fire prevention and insulation.

Electrical connectors: Connecting components such as terminals, plugs, and pins are usually composed of metal and insulating materials to ensure the stability of electrical connections and smooth transmission of current.

Features:

High-efficiency conversion: The main feature of AC-DC Power Board is efficient power conversion. Through internal rectification, filtering, voltage stabilization and other links, the power board can stably convert the input AC power into precise DC output to meet the voltage and current requirements of different devices.

Strong stability: AC~DC Power Board uses high-quality electronic components and is designed with perfect current protection and overvoltage protection functions, so that it can maintain a stable output voltage during long-term operation and avoid equipment failure due to voltage fluctuations or excessive current.

Small and compact: AC~DC Power Board usually adopts a compact design and can provide efficient power conversion in a limited space, which makes it suitable for various small devices with limited space, such as electronic products, household appliances, etc.

High safety: AC~DC Power Board generally has a variety of protection functions, such as overload protection, overvoltage protection, short circuit protection, etc., to ensure the safe operation of the power board and connected devices. Especially in the power conversion process, the power board design will focus on anti-interference, anti-overvoltage and other functions.

Wide adaptability: AC~DC Power Board can support a variety of AC input voltages (such as 110V, 220V, etc.), adapt to the power standards of different regions and countries, and its output voltage is also diverse to meet the needs of different electronic devices.

Advantages:

High efficiency and low power consumption: Due to the use of efficient power conversion technology, AC~DC Power Board can convert AC power into DC power with low power loss, which enables it to maintain low energy consumption during long-term operation, thereby saving electricity and reducing equipment operating costs.

Miniaturization and lightweight: Compared with traditional large transformers and power supply equipment, AC~DC Power Board is small in size and light in weight, suitable for environments with limited space, especially in portable devices and small electronic devices.

Long life and high reliability: The design of AC~DC Power Board usually focuses on the durability and stability of components. It uses high-quality materials and precise manufacturing processes, can maintain efficient operation for a long time, and has a long service life, reducing the maintenance cost caused by frequent replacement of power boards.

Multiple protection functions: AC~DC Power Board is often equipped with overload, overvoltage, short circuit and other protection functions to ensure that the power board or connected equipment will not be damaged when abnormal conditions occur in the equipment, increasing the safety and reliability of the system.

Wide range of applications: Whether it is consumer electronics, industrial automation equipment or communication equipment, AC~DC Power Board can provide stable and reliable power supply. Therefore, it has been widely used in various electronic products.

FAQ:

Does AC-DC Power Board support the use of high-power devices?

The power capacity of AC-DC Power Board is limited and is generally suitable for small to medium-sized electronic devices. If you need to provide power for high-power devices, you need to choose an AC-DC power board with a higher rated power. High-power applications require the use of specially designed high-efficiency power boards that can handle larger current loads while ensuring the stability of the output voltage.

What is the power conversion efficiency of AC-DC Power Board?

The power conversion efficiency of AC-DC Power Board is usually high, generally reaching more than 80%. The specific efficiency is affected by factors such as input voltage, output current and the quality of internal components. High efficiency means less power waste and lower heat generation, thereby improving the stability and safety of the device.

Will the use of AC-DC Power Board generate electromagnetic interference?

AC-DC Power Board may generate certain electromagnetic interference (EMI) during operation, especially in high-frequency switching power supplies. In order to reduce this interference, many power boards use EMI suppression technology, such as shielding, filtering and electromagnetic compatibility (EMC) design. Choosing an EMC-certified AC-DC Power Board can effectively reduce the impact of interference on surrounding electronic devices.

Can the output voltage of the AC-DC Power Board be adjusted?

For some high-end or special models, the output voltage can be adjusted by adjusting the potentiometer or digital interface. This adjustable voltage function is particularly suitable for occasions where voltage requirements need to be switched between multiple devices. For example, in laboratories, R&D environments, or some industrial applications that require precise voltage control, using an AC-DC Power Board with adjustable voltage can provide greater flexibility and adaptability. However, users need to follow the regulations in the product manual when adjusting the voltage to ensure that the adjustment range does not exceed the maximum output capacity of the power board, otherwise it may cause power damage or unstable output.