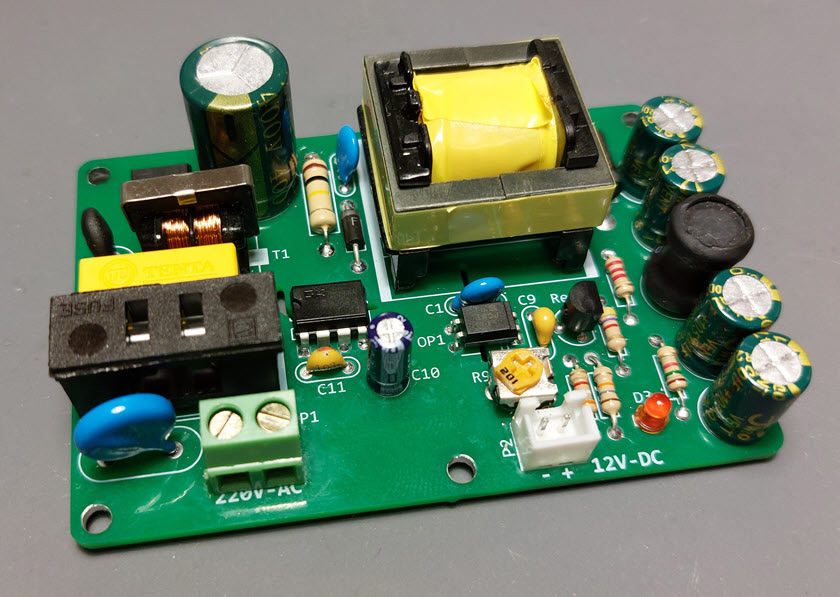

PCB AC/DC converter is a power module that converts alternating current (AC) into direct current (DC) and is widely used in power electronic products. This type of converter is usually used for integration and customization on circuit boards, and can provide stable DC power for electronic devices. It usually uses switching power supply technology to efficiently convert power and is widely used in communication equipment, industrial control, home appliances, medical equipment and other fields.

Input and output specifications

Input specifications: The input voltage is usually alternating current (AC), such as 100V-240V or 90V-264V, which can adapt to the grid voltage in different regions.

Output specifications: The output voltage is usually standard direct current (DC), such as 5V, 12V, 24V, 48V, etc. The output current range varies according to the equipment requirements. Common output currents are 1A, 2A, and 5A. Different current values can also be selected according to customized requirements.

The input voltage and output voltage must be selected according to the actual load and application scenario. When designing, ensure that the input and output parameters of the converter match, otherwise it will affect the stability and operating efficiency of the equipment.

Power Capacity

Power capacity refers to the maximum power that the converter can provide, usually in watts (W). For example, a common 5V 3A converter has a power of 15W, while a 12V 2A converter has a power of 24W. Choosing the right power capacity is very important, and the following factors need to be considered:

Power demand: Choose a converter with the right power based on the maximum power demand of the load.

Overload margin: Choose a converter that is slightly higher than the maximum power demand to cope with power peaks in a short period of time.

Efficiency: High-efficiency converters can reduce heat loss and energy consumption.

Working environment and temperature

Working environment: PCB AC/DC converters are generally suitable for temperature and humidity controlled environments. Ambient humidity should generally be less than 90%, and avoid harsh factors such as excessive dust, corrosive gases, and strong vibrations.

Working temperature range: Most converters have an operating temperature range of -10°C to +60°C. Extreme working environments may require the selection of special temperature control designs, such as industrial-grade converters, which can support a wider temperature range (for example, -40°C to +85°C).

Heat dissipation problem: Excessive operating temperature may cause the device to overheat, affecting performance and life. Therefore, it is crucial to choose a converter with good heat dissipation design (such as aluminum alloy housing, heat sink or fan).

Features

High-efficiency conversion: Modern AC/DC converters use switching power supply technology, which has higher efficiency (usually more than 80%-90%) than traditional linear power supplies, which can reduce energy waste and reduce heat generation.

Compact size: Most PCB AC/DC converters are compactly designed, easy to integrate into circuit boards, saving space.

High stability and reliability: High-quality components are used to ensure long-term stable operation of the converter.

Multiple output options: Supports a variety of output voltage and current specifications to adapt to various load requirements.

Built-in protection functions: Including over-current protection, over-voltage protection, short-circuit protection and over-temperature protection to ensure that the converter operates safely in harsh environments.

Advantages

Energy saving and high efficiency: Using switching power supply technology, high conversion efficiency, reduced energy loss, and reduced electricity costs.

Space saving: The compact size design is easy to embed into electronic devices, which helps save equipment space.

Strong reliability: With multiple protection functions, it can effectively prevent overload, overvoltage, short circuit and other faults, and extend the service life of the equipment.

Low heat generation: High-efficiency conversion means less heat generation, which helps to keep the system stable and avoid equipment damage due to overheating.

Wide applicability: It is suitable for home appliances, communications, medical, industrial control and other fields to meet various application needs.

Scope of use

Consumer electronics: such as TVs, audio, computer equipment, etc., require a stable DC power supply.

Communication equipment: such as routers, switches, signal processors, etc.

Medical equipment: such as ultrasonic equipment, monitoring instruments, blood pressure monitors, etc., require a stable and efficient power supply.

Industrial control: used for industrial equipment, automation control systems, power equipment, etc., to provide stable DC power support.

LED lighting: LED driver power requires a stable DC power supply, usually using an AC/DC converter.

The most common problem

Overheating problem: If the converter cannot dissipate heat effectively, it may cause overheating, which will affect its performance and service life. It is necessary to ensure that the appropriate power is selected and appropriate heat dissipation measures are taken during use.

Unstable output: If the converter has output voltage fluctuations, it may affect the connected load devices. Possible reasons include poor design, aging components, unstable input voltage, etc.

Low power efficiency: Some low-quality converters may have low efficiency, resulting in higher energy loss and heat. Choosing efficient converters can reduce this situation.

Failure of overload protection: If the converter's protection function is insufficient or not configured as required, it may not effectively protect the load or device when overloaded.

Compatibility issues: Some devices require specific output voltage or current, and incompatible AC/DC converters may not work stably.

In short, choosing a suitable PCB AC/DC converter requires comprehensive consideration of factors such as input and output specifications, power requirements, working environment, protection functions and efficiency to ensure its reliability and long-term stability in the intended application.